3D Printing and Bio-printing - Revolutionizing Healthcare

3D Printing, also known as Additive Manufacturing (AM), enables development of non-traditional production methods, enabling lighter, stronger parts. AM, as its name implies, refers to a group of fabrication techniques that literally add material to create an object, by fabricating in layers to produce an object from a CAD file. It is very quickly emerging as a disruptive approach to industrial production. Ashwini Vaishnaw, Union Minister for Electronics and Information Technology recently said, “This is the cutting edge, this is where the world is still moving forward and this is the time to take the lead and time to make the right moves.” In fact, AM technologies are now being widely used across medical devices industry.

How 3D Printing is helping the Dentists?

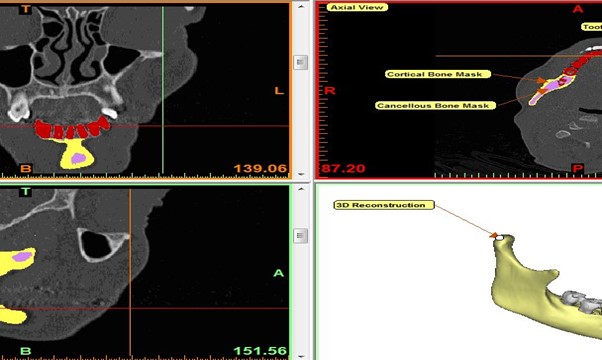

3D Printing has significant benefits in the field of healthcare. With 3D Printing, dentists can make patient-specific dental implants, surgical guides, braces, aligners, dental crowns, and bridges. In the present era, driven by fast-moving technologies, dentists are using 3D Printing technology to create a three-dimensional dental model of the patient jaw to minimize the risk that might occur while performing a surgery.

Steps in Digital Dentistry:

To use 3D Printing in the dental domain, the following steps are followed:

Step 1: Scanning

Initially scanning is done in the patient jaw or the area in which surgery will be performed. To check those areas, specific dental scanners are used and after collecting the digital data it will be proceeded to the next step.

Step 2: Design Modification & Preparation

The digital data from the scanner will be processed using reverse engineering software with required change in the model. Then the model will be sent for printing.

Step 3: Printing & Post Processing

The processed model is now taken into the slicing software, where required print settings, orientation and scaling will be provided to get the tool path file. Now this tool path file is sent to the printer for printing. After the printing gets completed, the physical model goes through various post processing steps to get better strength and surface finish.

Benefits : Use of AM techniques in dentistry leads to three main effects:

- Reduced operating time

- Improved Patient outcomes

- Less Interoperative Bleeding

What is Bio-printing?

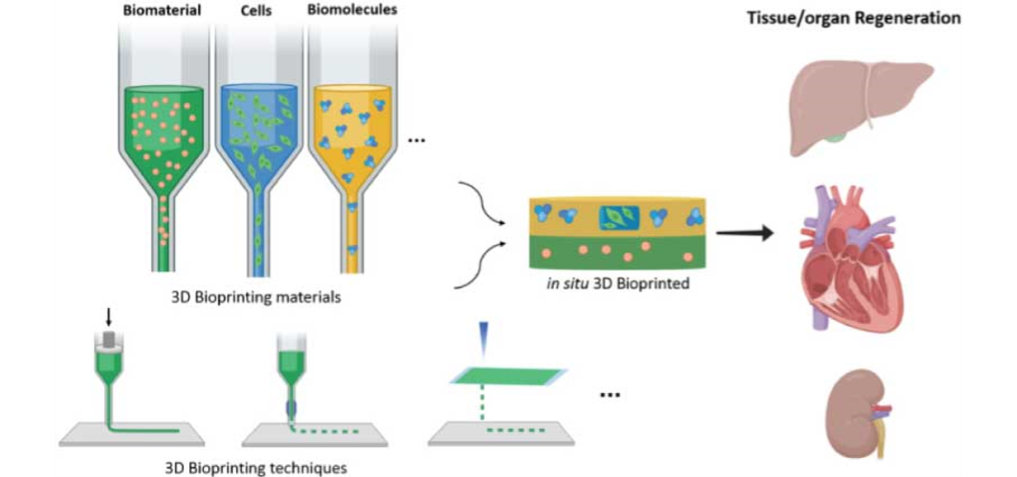

Bio-printing is similar to 3D Printing technologies, the only difference is that bio-printers use bio-materials or bio-inks to create or print organ or tissue-like structures that let living cells multiply and grow like human tissues. Bio-printing has enormous potential to benefit the healthcare and cosmetics industry.

How Bio-printing will change the future healthcare?

Research is still going on in the field of bio-materials and bio-inks, but bio-printing can make a huge impact in these areas of healthcare such as –

- Drug Development

- Artificial Organs

- Wound Healing or Plastic Surgery

Steps in Bio-printing

There are three steps involved in Bio-printing-

1. Pre-Bioprinting

Digital CAD file is prepared for the printer to read. These digital cad files can be prepared with the data collected from CT&MRI scans. Along with the assistance of doctors, living cells are prepared and mixed with bio-inks.

2. Bioprinting

The prepared bio-inks are loaded into the printer’s cartridge and the required print head is chosen to print the organ or tissue like structures.

3. Post-Bioprinting

Most of the printed structures are cross-linked to become fully stable. Generally, cross-linking is usually done by treating the structure with either ionic solution or UV light. Then the cell-filled structures are placed inside an incubator for cultivation.

IEEE Computer Society predicts (https://ieeecs-media.computer.org/media/tech-news/tech-predictions-report-2022.pdf) that 3D printing in healthcare will enable prosthetics, protective equipment, custom surgical equipment, patient sample collection, and safer implants.

To know more about this, visit-https://learn.futureskillsprime.in/pathways/getting-started-with-3d-printing-amp-modeling?utm_source=FSPCoursePage_Pathway3DPrinting_ApplyNow&utm_medium=WebsitePathway&utm_campaign=FSPWebsite

Written by NIELIT Calicut