All about Additive Manufacturing and 3D Printing

Additive manufacturing (AM), also known as 3D printing, enables development of non-traditional production methods, enabling lighter, stronger parts. AM, as its name implies, refers to a group of fabrication techniques that literally add material to create an object, by fabricating in layers to produce an object from a CAD file. It is very quickly emerging as a disruptive approach to industrial production that creates lighter, stronger parts and systems.

A combination of composite techniques with additive manufacturing is being widely adopted in areas such as defence, marine, aerospace, and for other industrial uses. It’s the disruptive future - where an end-to-end manufacturing process will take 90% less time and consume 80% less energy.

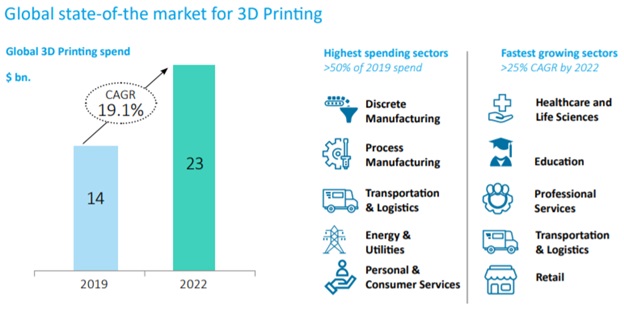

Additive manufacturing or 3D printing technology is projected to touch a market of US $20 Bn by 2020, while the same market in India is expected to be worth USD 79 Mn by 2021. The trend of moving out of the conventional will make things lighter and faster. As a result, the demand for carbon-fibre (CF) has seen a large growth and companies are working on automated composite manufacturing (ACM).

Additive Manufacturing in India

For years, additive manufacturing and 3D printing have been put to work in India for concept modeling, design validation, prototyping, and some tooling. Organizations in India are showing the same interest as those in the U.S., Germany and other countries to adopt AM for production applications. The major driver for market growth is the rising demand in electrical and electronic, renewable energy, building & construction and fresh water transportation, sewage treatment systems to support our government’s drive to build smart cities. Manufacturing capabilities also need to be greatly improved to supply critical components to the defence sector.

Indian industries are adopting an aggressive approach in R&D to bring about in reforms to Indian manufacturing with emerging technologies like Additive Manufacturing.

An emerging technology

Sectors like automotive, healthcare and defence are very quickly adopting this technology, with medical pre-surgery and the education sector marching right behind. The tallest 3D printed installation shaped like a Banyan Tree called 'Jhada' was installed at Chhatrapati Shivaji International Airport in Mumbai using 3D printing technology and AM technology in India. The slow pace at which this technology is being adopted in India can be attributed to a lack of understanding about 3D printing/AM, lack of investment and fewer R&D centres.

Current and emerging trends

Additive manufacturing is emerging out of the prototyping and PoC, having been proved viable for the market, to become a mainstream technology for serial production, for aftermarket parts production, utilization of waste-turned-composite materials, composite metal printing, and other customized products.

Adjacent market developments supporting 3D Printing adoption

Composite Manufacturing

End-of-life recycling or refurbishing by conversion of disposed waste into new composites, or refurbishing through 3D printed retrofitting’s

3D Printed-to-Order

Mass customization of consumer products through 3d printing technology, particularly in healthcare and consumer durables

3D Printing Business

Models Inclusive evolution of use cases and 3D machinery and materials spawning new business models

Production Value Chain Visibility

Input and output traceability, end-to-end inventory visibility and product backup, and product design and IP protection

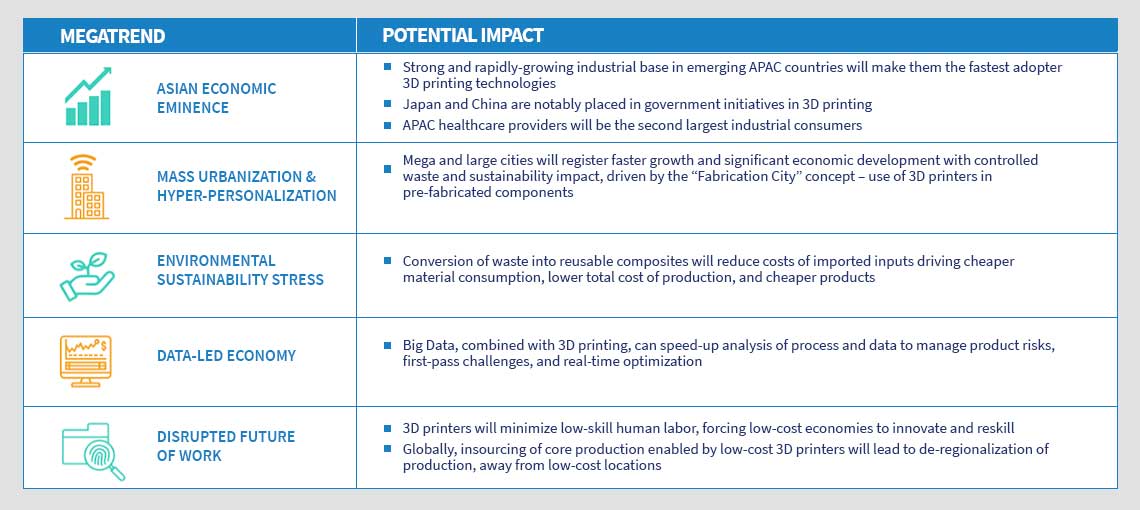

3D PRINTING Impact on megatrends and emergent use cases

3D printing is delivering results - production throughout is rising and the range of materials and their composition palette is expanding, while the cost of production is declining - driving wider adoption across sectors to address global challenges. Recent growth in the 3D printing ecosystem has paved the way for new entrants from start-ups and small, local-scale vendors, to large and global software companies vying for a pie of the fastest-growing 3D printing software market while spawning use cases for global resource, consumption, and optimization impact.

Potential impact of 3D Printing on emerging global megatrends

Additive Manufacturing / 3D Printing

3d printing, could eventually lead to largely boosting production for SMSEs by increasing the normal output of small and cottage enterprises, allowing them to use their economies of scale to become profitable with rapid prototyping and additive manufacturing.

Job Roles:

Software Engineer-Slicing | 3D Modelling Engineer/3D Graphic Artist | Solution Architect | System Test Engineer | 3D Printing Technician | Material Analyst Engineer I Mechanical Expert Engineer- 3D Printing/ Additive Manufacturing

Given the widespread adoption of 3D Printing and modelling technology, learners must know about the 3D printing process, the technology behind it and how it is used in different industries. Learners can start with their 3d printing courses on FutureSkills Prime, at no cost.